Industrial Equipment Failures and Construction Disputes

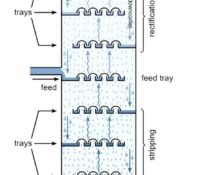

At Warren, we frequently investigate losses involving industrial machinery. Many of the losses involve workplace injuries, fires, or explosions; however, we also analyze industrial machinery and processes for other types of problems. For example, we analyze failures of machinery or industrial processes to perform as expected or disputes that arise from the commercial supply and construction of such systems. This can encompass a range of issues from failure to achieve required levels of product quality or production quantity, to matters concerning unclear specifications or contracts, Read More