Machine Guarding Resources

Leave a CommentSo, you find yourself with a machine hazard that you need to guard. Where do your turn for guidance regarding guards? Several resources are available for the person who is tasked with providing machine guarding.

The United States government provides resources in the Code of Federal Regulations (CFR). These can be found at www.ecfr.gov. Title 29 of the CFR, section 1910 covers “General Industry” regulations. 1910 Subpart O, covers Machinery and Machine Guarding. Definitions are covered in 1910.211 and it is wise to understand how terms are defined. For instance, in 1910.211(a)(1), Point of operations is defined by the regulation as “that point at which cutting, shaping, boring, or forming is accomplished on the stock.”

29CFR 1910.212 is titled “General requirements for all machines” and 1910.212(a)(1) Types of guarding, states that “one or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation, ingoing nip points, rotating parts, flying chips and sparks. Examples of guarding methods are – barrier guards, two-hand tripping devices, electronic safety devices, etc.”

29 CFR 1910.212 “General requirements” is not the only federal regulation out there. There are also regulations for specific equipment such as 1910.213, Woodworking machinery requirements, 1910.215 Abrasive wheel machinery, 1910.216 Mills and calendars in the rubber and plastics industries, 1910.217 Mechanical power presses, 1910.218 Forging machines, and 1910.219 Mechanical power-transmission apparatus.

CFR 1910 Subpart R – Special Industries includes, but are not limited to 1910.262 Textiles, 1910.263 Bakery equipment and 1910.268 Telecommunications. Specific industries are also covered, including Maritime (29 CFR 1915, 1917, 1918), Construction Industry (29 CFR 1926) and Agriculture Industry (29 CFR 1928).

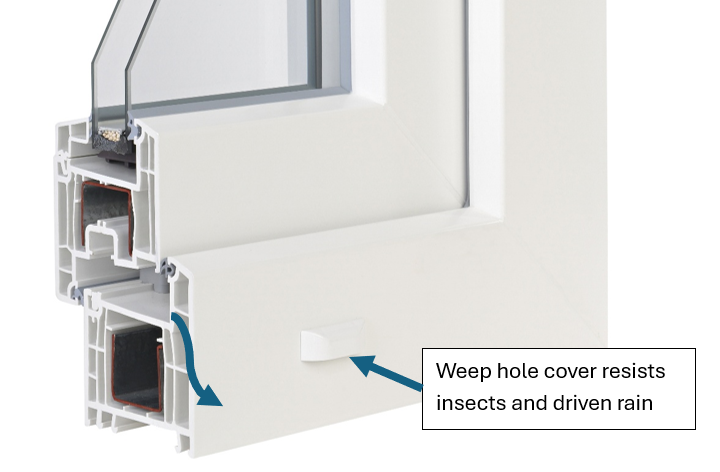

But what about the details of the design for a guard? 29 CFR 1910 (a)(2) General requirements for machine guards reads as follows, “Guards shall be affixed to the machine where possible and secured elsewhere if for any reason attachment to the machine is not possible. The guard shall be such that it does not offer an accident hazard in itself.”

Here we see that per OSHA the guard should protect the operator from hazards such as those created by point of operation, ingoing nip points, rotating parts, flying chips and sparks. Also the guard needs to be affixed to the machine where possible. What other resources are available for the person tasked with designing a guard?

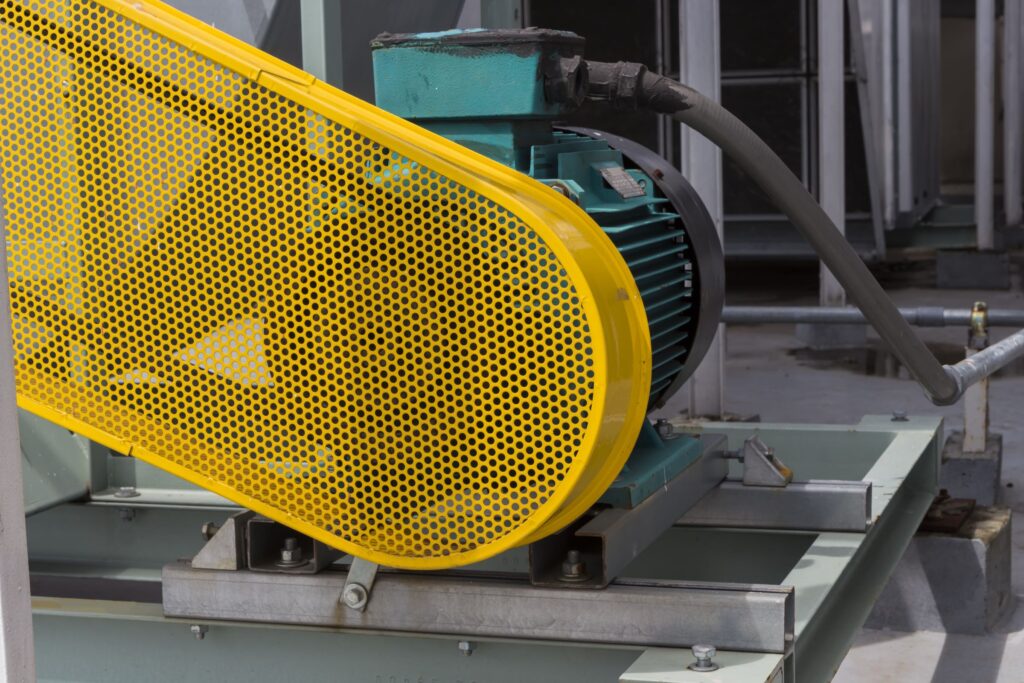

Fixed Guard on a Rotating Shaft

Here consensus standards are available to assist with the task. The American National Standards Institute (ANSI) publishes B11.0 – Safety of Machinery. The standard states in 7.9 Safeguarding, 7.9.1 General, that the guards, safeguarding devices, awareness devices, and safeguarding methods on machinery shall conform to the applicable ANSI B11 machine-specific (Type-C) standard and/or ANSI B11.19. ANSI provides standards for specific equipment including mechanical power presses as an example. If there is no machine specific standard available, then ANSI B11.19, Performance Requirements for Risk Reduction Measures: Safeguarding and other Means of Reducing Risk is available.

ANSI B11.19-2019 (R2024) contains a specific section on guards, including fixed guards, movable guards, interlocked guards, adjustable guards, self-adjusting guards, partial guards, perimeter guards, nip guards, and shields. This standard can be used to assist the individual tasked with designing a guard.

Fixed Guard on Belts

International Standard ISO 14120 Safety of machinery – Guards – General requirements for the design and construction of fixed and movable guards is also available to assist in the design of guards for machinery. Some sections included in this standard are “Principles for the design and construction of guards” and “Selection of types of guards.”

The individual tasked with designing a guard has several resources available to assist in the design. Proper application can lead to a safer piece of equipment.

Chad Jones, PE, CFEI, CVFI, CMSE has a Bachelor of Science in Mechanical Engineering from Clemson University. Chad has over 25 years of engineering experience including mechanical, process, and manufacturing engineering. This work has included equipment design, machine safeguarding, cost estimating and safety compliance. Chad also has over 15 years of commercial, industrial, and residential HVAC and plumbing design experience. A lifelong auto and motorcycle enthusiast, Chad is accomplished in the maintenance, repair, and modification of vehicles and engines. Chad is a Certified Fire and Explosion Investigator, Certified Vehicle Fire Investigator, and IFSAC certified Firefighter II in Greenwood County, South Carolina.