Industrial ovens and furnaces are used in many manufacturing processes. One use of industrial ovens is for drying and curing coatings on fabrics.

We investigated a fire loss involving a very large oven, 10 stories high, used for curing coatings on an industrial fabric. A young firefighter was burned in response to this fire, one of a string of many fires that had occurred involving the oven.

The investigation revealed that the fire occurred when a recirculation fan failed due to a broken shaft and therefore stopped circulating air. A gas burner that fired into this recirculation loop continued to operate and overheated the area due to the lack of airflow. This overheating ignited combustible residues that build up inside the oven and on its exterior due to leakage through the old ovens walls.

The fire spread up the walls due to this combustible residue, eventually to the location where the firefighter was injured.

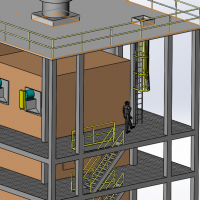

Figure 1. A CAD model of the building containing the large oven where the fire occurred. This model was created for a Warren supplied animation used in litigation arising from the fire. Each level is equivalent in height to a story of a high rise building.

NFPA 86, Standard for Ovens and Furnaces, is the widely acknowledged standard for the proper design and use of industrial ovens. Several of its provisions were not followed in the equipment installed at the subject site. The oven should have been equipped with air pressure switches on the recirculation fans that would have stopped the burner if the fan failed to operate. Also, a properly located high temperature limit switch would have sensed the abnormal elevated temperatures in the burner chamber and shut off the burner. We were also critical that a lack of ongoing cleaning at the plant allowed the accumulation of sufficient combustible residue to spread the fire. Finally, the oven lacked a fire extinguishing system that could have extinguished the fire prior to its spread. After our investigation, we testified at deposition about the above problems on behalf of the injured firefighter’s legal representatives. Shortly thereafter, the case settled on a favorable basis.

Founded in 1997, The Warren Group, forensic engineers and consultants provides technical investigations and analysis of personal injury and property claims as well as expert testimony for insurance adjusters and attorneys. Extremely well versed in the disciplines of mechanical, electrical, chemical, structural, accident reconstruction and fire and explosion investigation, our engineers and consultants are known for delivering the truth — origin, cause, responsibility and cost of an event or claim — with unmistakable clarity.