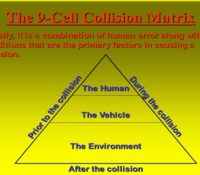

The 9-Cell Collision Matrix – The Environment

“Was a dark stormy night as the train rattled on…” Anybody? 1985? Scarecrow? Come on… this was when Cougar was still a Mellencamp! Ok… it was called Grandma’s Theme… you’ll have to look that one up… but as I sat down to write this blog on the environment, that song kept running though my head. If you look it up, it will have a similar effect… just a little warning.

In our last installment of the 9-Cell Collision Matrix let’s travel down the wet, slippery slope of environmental factors that can contribute to car crashes, and maybe take a closer look at the things around us, at or near our crash scene that may reveal some important clues. Read More