Understanding Heat Transfer: A Guide for Fire Investigators

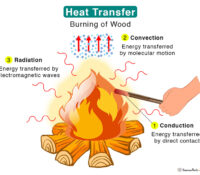

In the realm of fire investigation, understanding heat transfer is crucial. Heat transfer plays a significant role in how fires start, spread, and ultimately, how they can be analyzed and investigated. There are three primary modes of heat transfer: conduction, convection, and radiation. In this article, we’ll delve into each of these modes and explore examples of how fire investigators can apply this knowledge to their work. Read More