Lighting systems in buildings and other structures have undergone changes over the years. Many of these changes have occurred as manufacturers have developed more efficient lighting methods. Lighting loads can represent the largest category of electrical load in many buildings, thus improved lighting efficiency may significantly lower your power bill and can lengthen time between lamp changes.

For many years, large diameter T12 fluorescent light fixtures using magnetic ballasts were the standard lighting design used in many commercial facilities like offices and retail stores. Smaller diameter and more efficient bulbs like T8 and T5 designs were created which have limited the use of T12 bulbs to select replacement use. T8 or T5 lamps with an electronic ballast became the standard lighting design.

Improvements were also made in fluorescent lamp ballasts. Magnetic ballasts were replaced with electronic ballasts that allowed a better regulation of the lamp’s power and use of more efficient high frequency power. Today, there are a wide variety of lamps and ballasts available that enable changing older fluorescent lights into T8 and T5 technology lighting that saves energy and extends lamp life. Even more efficient tubular lamp LED technology is now available.

All these changes in lighting designs to reduce energy use and lengthen lamp life sound great. However, the variety of designs and the detailed differences between designs create the potential for mistakes when retrofitting light fixtures. Some of these mistakes can cause fires. Warren has investigated several fires caused by improper modifications to fluorescent light fixtures. Figure 1 is an example of a small fire that started at a fluorescent light fixture retrofitted with LED lamps.

One source of potential problems is the wide variety of available ballasts, lamp holders and lamps, not all of which are compatible. When selecting components for a retrofit project, compatibility between the fluorescent ballast and lamps should be verified with the component manufacturers. This is also true for LED lamp retrofits which use an existing fluorescent ballast. Still another variation are LED lamps designed for direct connection to the supply voltage without the use of a ballast. This approach further increases efficiency as the load from the ballast is eliminated.

Another potential problem is the possibility of miswiring the light fixture when replacing the internal components. The manufacturer’s exact wiring diagram and installation instructions should be followed. In fact, Article 110.3(B) of the National Electrical Code requires that listed or labeled products be installed in accordance with any instructions included in their listing or labeling. Miswiring of a light fixture can increase the current flow in conductors and through connections, increasing the potential for a fire.

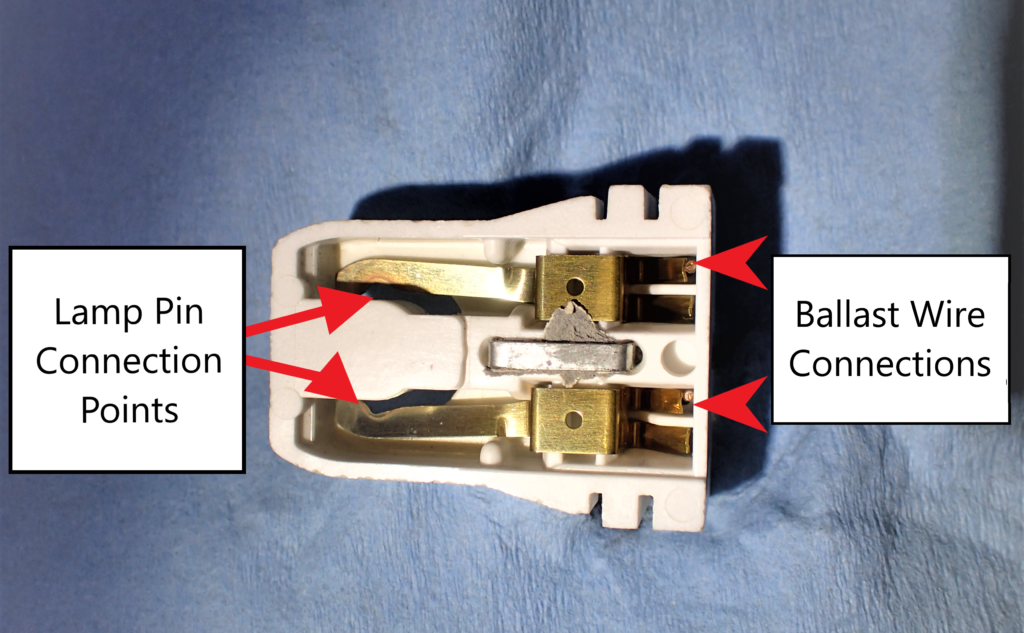

Another common retrofit problem involves the lamp holders that are used to both hold and power the lamps. The lamp holders are often called tombstones due to their unique shape. Lamp holders connect the ballast conductors to the ends of the lamps. The wiring from the ballast is typically held by the spring force of the metal part of the lamp holder. The pins of the lamp are held by the spring force of the upper part of the lamp holder arm. Figure 2 shows a normal lamp holder of the un-shunted type with its back cover removed. Shunted lamp holders have the two connecting arms internally connected (shunted) which is a requirement for certain types of ballasts. Note the ballast wire and lamp pin connection locations.

In certain cases, the connections between the lamp holder and the lamp pins or ballast wiring can degrade and overheat, even to the point of igniting the lamp holder. The potential for this occurrence is elevated when the fixture is either improperly wired or if (when required) the two sides of the lamp holder are not shunted, either by use of a shunted lamp holder or by external connection. The overheated connection can proceed to ignite local combustibles that can spread to cause a structural fire. Figure 3 shows a lamp holder that was not shunted and was improperly wired, which caused it to overheat and cause a fire in the fixture.

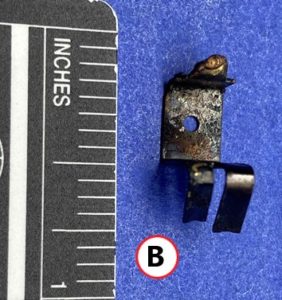

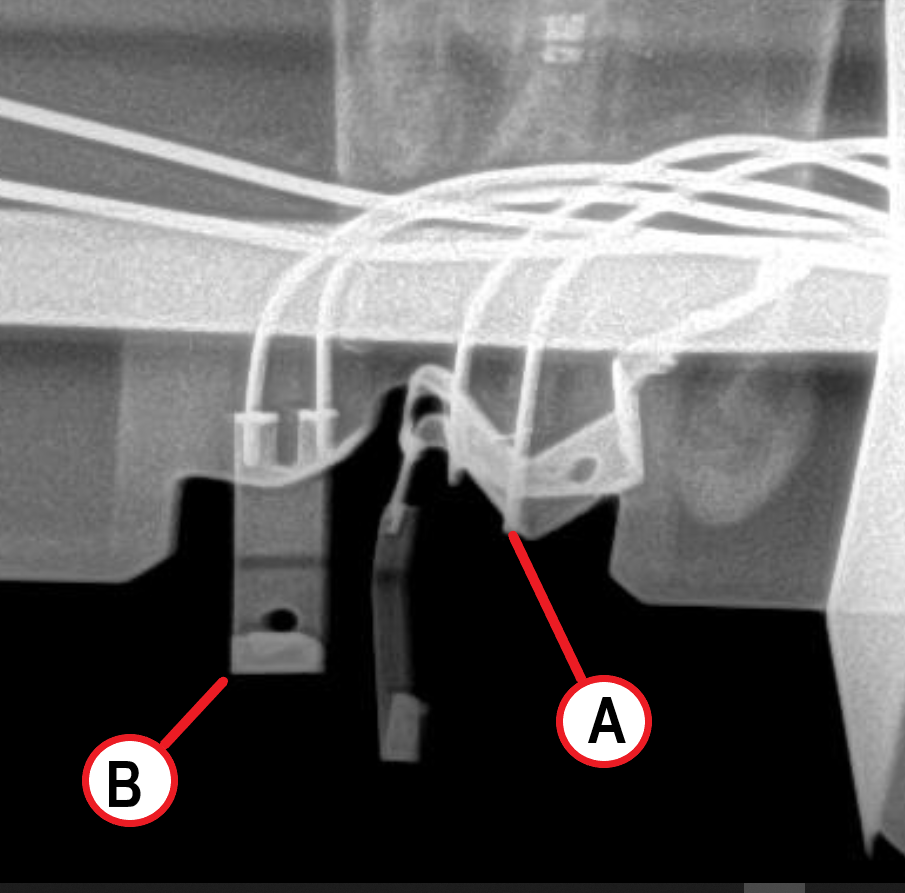

When this overheating occurs, characteristic damage to the lamp holders typically ensues. Figures 4 and 5 are the metal parts after removal from the burned lamp holder. Figure 6 is an X-ray image of a fluorescent tube lamp holder that overheated and caused a fire. Care should be taken to retain all debris near the origin area when investigating a fire suspected of originating at a light fixture. Locating these small metal parts may be helpful in determining if a problem with the light caused the fire.

Figure 6: Image of a fluorescent tube lamp holder that overheated and caused a fire. The X-ray was taken of the lamp holder while still in the fixture.

The above sections have highlighted a few unique conditions that have led to fires originating at fluorescent light fixtures. However, other conditions at the fixture, such as ballast failures or poor wiring connections at the ballast supply might also cause fires. In any case, if you have a fire that appears to have originated near a fluorescent light fixture, Warren has the experience required to help determine the cause of the fire.

Founded in 1997, The Warren Group, forensic engineers and consultants provides technical investigations and analysis of personal injury and property claims as well as expert testimony for insurance adjusters and attorneys. Extremely well versed in the disciplines of mechanical, electrical, chemical, structural, accident reconstruction and fire and explosion investigation, our engineers and consultants are known for delivering the truth — origin, cause, responsibility and cost of an event or claim — with unmistakable clarity.