In the three-part series on the CE mark, we scratched the surface of some of the requirements an equipment manufacturer must meet in order to earn this designation. Part three of the series dealt with some of the requirements for the design of a guard. One of the items for consideration with the design of a guard is the frequency that someone will need to access the area protected by the guard. If access is needed on a routine basis, often defined as more than once per shift, the guard needs to be designed to be movable instead of fixed. Movable is defined as able to be opened without the use of tools. Otherwise the frustration and time requirements of obtaining tools and removing a fixed guard will often lead to the guard being discarded.

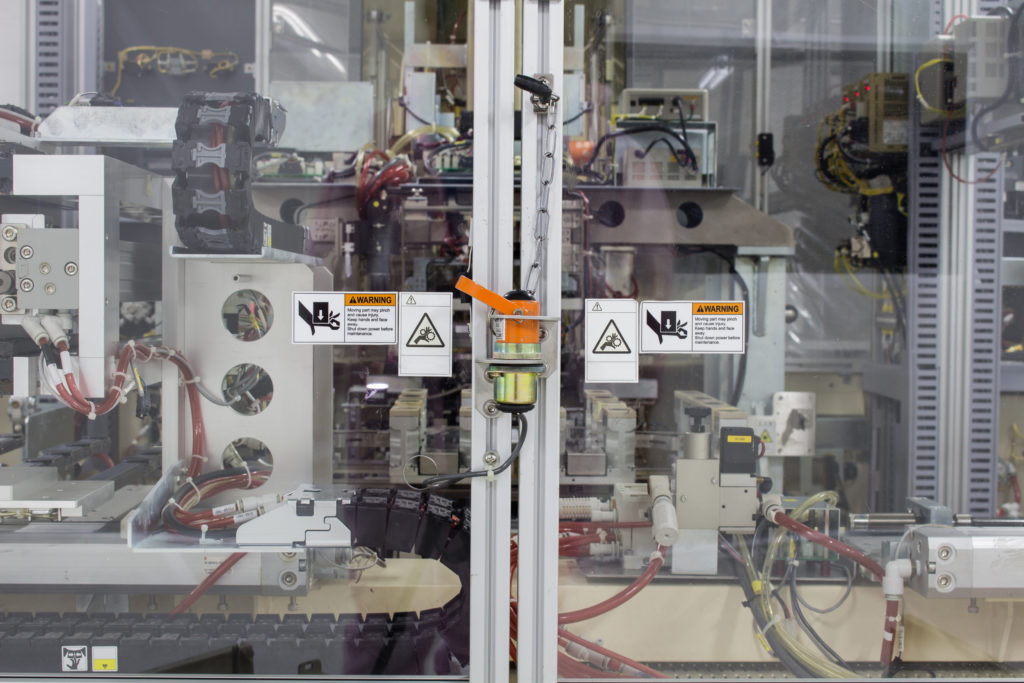

However, once you make the guard movable, how do you ensure that the guard is in place when it needs to be? The answer is an interlocking guard. Here the ISO standards give us more guidance with ISO 14120, Safety of machinery-Guards-General requirements for the design and construction of fixed and movable guards.

The first sentence in the Scope section of the standard reads:

“This International Standard specifies general requirements for the design and construction of guards provided primarily to protect persons from mechanical hazards.”

ISO 14120 defines the term “interlocking guard” in the following way:

“guard associated with an interlocking device so that:

-the hazardous machine functions ‘covered’ by the guard cannot operate until the guard is closed;

-if the guard is opened while hazardous machine functions are operating, a stop instruction is given;

-when the guard is closed, the hazardous machine functions ‘covered’ by the guard can operate, but the closure of the guard does not by itself initiate their operation”

So, what is an interlocking guard, have you ever thought about it? A perfect example is the lid on your clothes washing machine. In the very early days of the washing machine, the drum of a washing machine was not even covered with a lid creating a dangerous condition in the form of motion hazards. A guard was added over time to address this hazard in the form of an enclosure with a lid, but the machine would still operate with the lid open. Further improvements to the guard led to the addition of a lid switch, which is an interlock, to prevent the drum from spinning when the lid was open. These could often be defeated with a simple paperclip or fingertip by curious people, like young boys who like to see how things work! The new washing machine we have at home features not only an interlock to prevent the spin cycle from happening when the lid is open, but also a locking feature to prevent the lid from being opened while the drum is still in motion. This is actually an “interlock with guard locking”, as defined by ISO 14120 Section 3.6 below:

“interlocking guard with guard locking

guard associated with an interlocking device and a guard locking device so that:

-hazardous machine functions “covered” by the guard cannot operate until the guard is closed and locked;

-the guard remains closed and locked until the risk of injury from the hazardous machine functions has passed;

-when the guard is closed and locked; the hazardous machine function “covered” by the guard can operate, but the closure and locking of the guard do not by themselves initiate their operation.”

The crucial difference between the two is that the interlocking guard will not allow the machine to operate unless the guard in place but will still allow the guard to be moved or opened without the machine being in a safe, stopped position. An interlocking guard with guard locking will not allow you to open or move the guard until the hazardous motion has stopped.

Which one is right for your design? The risk assessment, discussed in Part 1 of the CE blog, comes into play in this selection. The hazard must be assessed and fully understood. The hazards associated with a rotating drum in a washing machine at full speed cannot be instantly made safe. It takes some time for the drum to wind down to a dead stop and eliminate the hazards of motion, hence the interlocking guard with guard locking to keep the lid shut until the drum stops. However, some hazards can be made safe almost instantly by a simple interlocking guard.

Another example very close to home is the microwave oven. The door is the guard that protects the user from the hazards associated with the operation of the magnetron and the microwaves produced inside the microwave oven. You cannot start the microwave with the door open. Also, the magnetron in the oven stops as soon as the door is opened, rendering the radiation hazard safe without the necessity of guard locking. Just be careful of the hot food!! It all goes back to the risk assessment where the hazards associated with the operation of the specific machine are identified and addressed to “achieve safety in the design of machinery.”

As the CE blogs and this one show, guard selection takes some serious consideration and design, and it is not to be taken lightly. Fortunately, we have consensus standards from both ISO and American National Standards Institute (ANSI) to help guide the designer through the process. In the next blog I will provide a brief glossary of standards that can guide machine designers in creating safe, effective, and user-friendly guards for both consumer and industrial machinery.

Chad Jones, PE, CMSE, CFEI has a Bachelor of Science in Mechanical Engineering from Clemson University. Chad has over 20 years of engineering experience including mechanical, process, and manufacturing engineering. This work has included equipment design, machine safeguarding, cost estimating and safety compliance. Chad also has over 10 years of commercial, industrial, and residential HVAC and plumbing design experience. Chad is a Certified Fire and Explosion Investigator and IFSAC certified Firefighter II in Greenwood County, South Carolina.