In Part 1, we looked at the basic parts of a fire sprinkler and took a closer look at other parts including heat responsive elements, wrench bosses, and kick springs. In this part, we’ll look at k-factors and deflectors.

K-Factor and Orifice Size

K-factor is a characteristic that relates water pressure to flow rate from the sprinkler, represented as k in the equation Q = k√P, where Q is flow (gpm) and P is pressure (psi).

If we supply water at 50 psi to a k-factor 5.6 sprinkler, the flow rate is 40 gpm. If we supply 50 psi water to a K25 sprinkler, the flow rate is 177 gpm. There are now sprinklers as large as K33.6, which would flow 238 gpm given 50 psi – big difference from the K5.6!

The most common k-factors are 5.6, 8.0, 11.2, 14, 16.8, 22.4 and 25. There are smaller and larger k-factors than these. For reference, K5.6 and possibly K8.0 are most often found in light hazard occupancies, with the possibility of a K11.2 extended-coverage sprinkler. K8.0 and K11.2 are more often found in ordinary hazard occupancies. K11.2 would fall between K8.0 and K14. K14 and larger are most often only found protecting rack storage warehouses or spec buildings anticipated to contain rack storage. There are sprinklers with orifices even larger than the nominal K17 (K16.8), including K22.4, K25 and K33.6. These giant sprinklers have one mission: to protect ever-taller warehouses with rack storage without needing in-rack sprinklers. In-rack sprinklers do an unmatched job of putting fire protection right where a fire could be and can support systems with lower water pressure requirements than ceiling-only protection. In-rack sprinklers are scorned, however, for their seeming ability to attract forklift contact which results in unintended water discharge, higher overall protection cost, and complication to the undertaking of re-arranging racks or changing tenants.

Deflectors

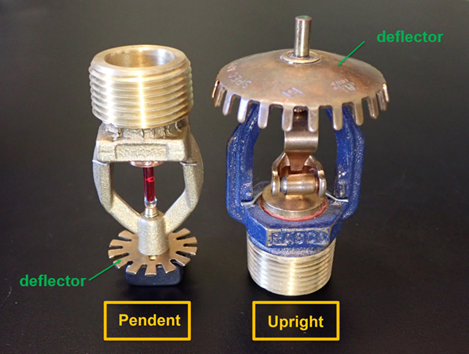

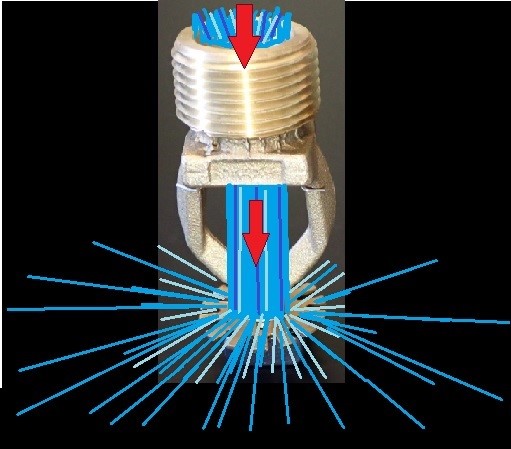

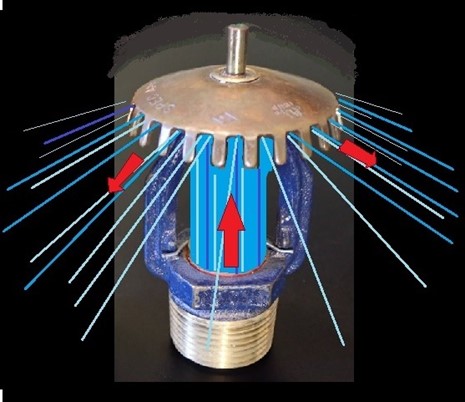

When a sprinkler is exposed to heat from a fire, the heat-responsive element activates and releases the water. The sprinkler’s deflector shapes, distributes, and directs the water. All other things being equal, the deflector’s shape defines the sprinkler’s orientation and purpose.

Deflector Materials of Construction

Sprinkler deflectors are typically made of high strength, corrosion-resistant alloys, including copper, bronze, or brass alloys.

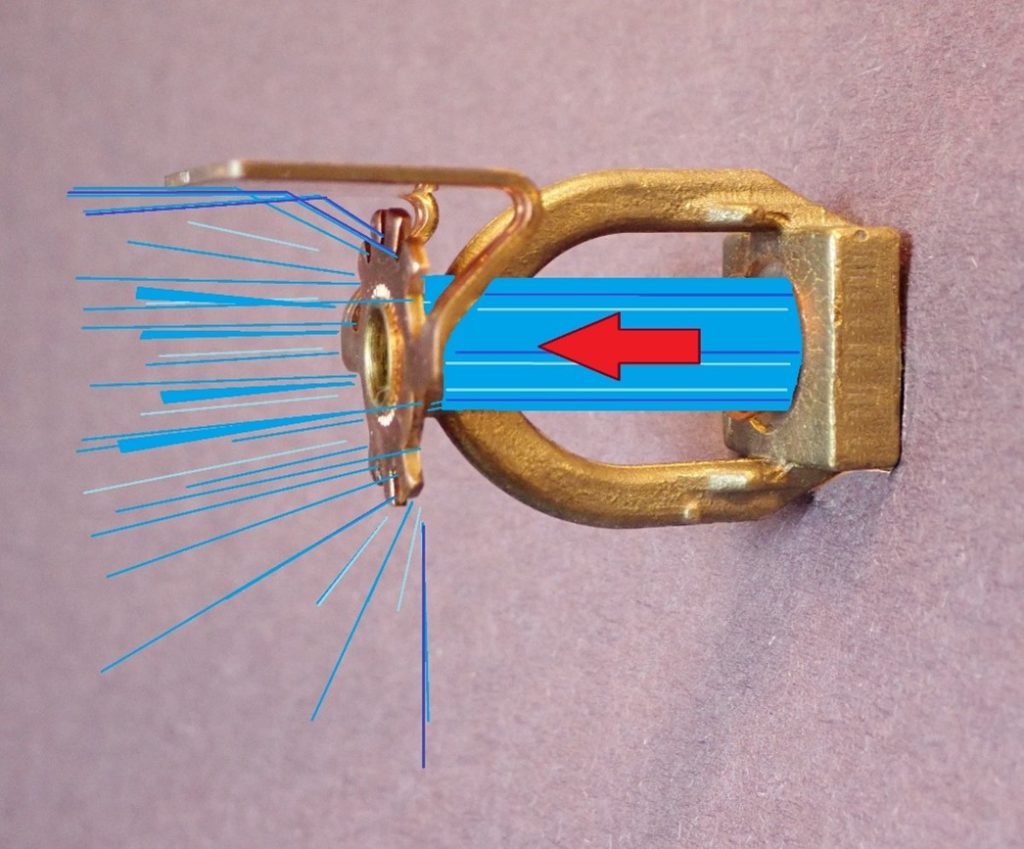

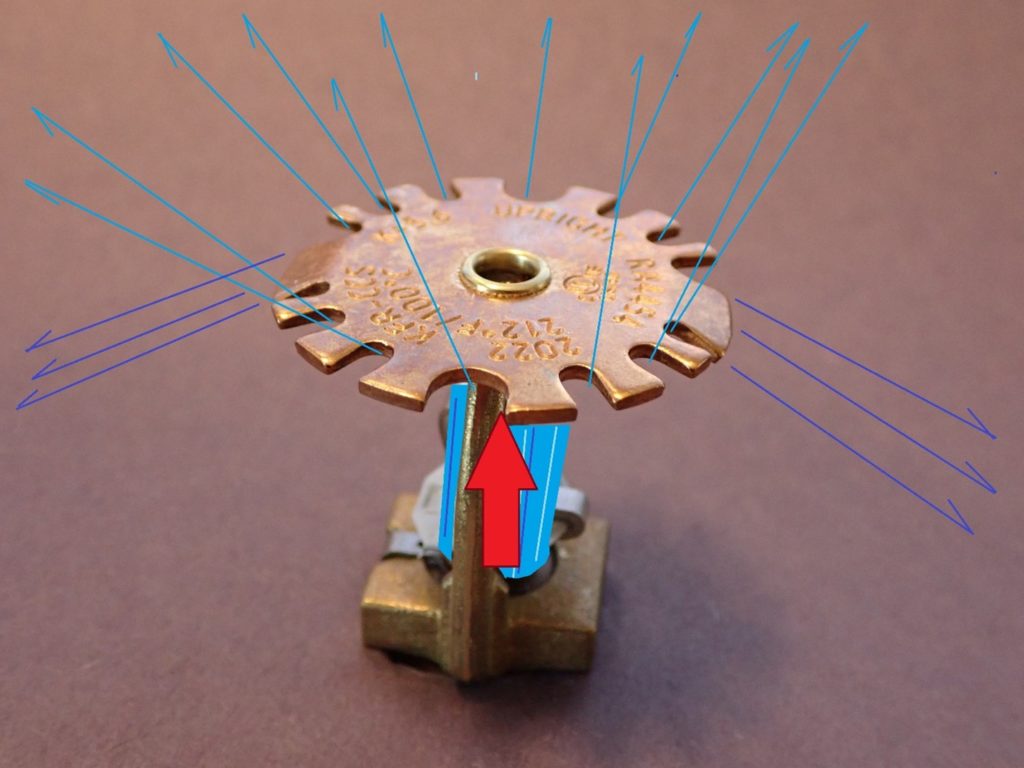

On the two basic sprinkler types, here’s how the water flows—

Figure: On a pendent sprinkler, which is installed with the threads above the deflector, the downward flowing water strikes the deflector and is dispersed in a roughly half-spherical shape.

Figure: On an upright sprinkler, which is installed with the deflector above the threads, water flows upward from the orifice. The water has to be redirected downward and dispersed, so the deflector is designed accordingly.

Variations on the Basic Theme

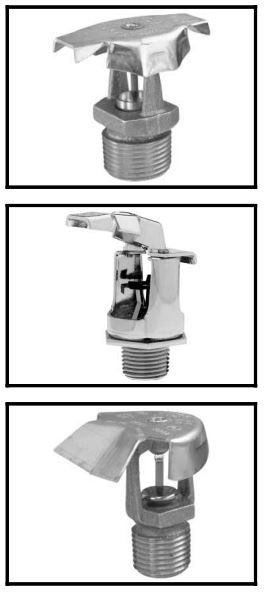

Expanding from the basic upright and pendent, other sprinkler types include (but are not limited to) horizontal sidewalls, combustible concealed space sprinklers, and attic sprinklers.

The (horizontal) sidewall could in theory have the same frame and heat responsive element as a pendant or upright of the same model, with the only change being the deflector.

Figure: On a horizontal sidewall sprinkler, which is installed with the deflector horizontal to the threads, water flows sideways from the orifice. On striking the deflector, the water fans outward but is prevented from moving upward by a canopy piece.

Figure: This upright combustible concealed space sprinkler’s deflector resembles that of a pendent sprinkler, but with some bent spokes. This deflector is intended to throw water mostly upward, with the two bent spokes directing a portion of the water downward.The award for the most unusual sprinkler deflectors has to go to the attic sprinklers.

The shapes of these seemingly odd deflectors have everything to do with where the sprinkler is positioned and where you want the water to go. The top-right sprinkler above is intended to be placed along a ridgeline, fairly close together, to throw water downwards from each side. The middle-right one throws a long narrow pattern only in one direction. The bottom-right one is a hip sprinkler; it is designed to throw a 90-degree pattern toward the eaves.

Now you know the parts of fire sprinklers, from boss to attic sprinkler deflectors, like a boss! Fire sprinklers are amazing and effective, with purposeful features that work in concert to squelch the fire hazard they were specifically designed for.

Amy Anderson, PE, CFEI, has a Bachelor of Science in Chemical Engineering from Clemson University and is a licensed Professional Engineer in Fire Protection, as well as a Certified Fire and Explosion Investigator. Amy has over 20 years of engineering experience including property loss prevention engineering specializing in fire protection, chemical and pharmaceutical facilities. She has partnered with clients to identify, assess, avoid, and reduce risk at their commercial and industrial properties. Additionally, she has assisted with the development of building and fire protection specifications, reviewed plans and performed site visits. She has reviewed project documents for compliance with applicable standards – construction, fire protection, process, and combustible dust hazards. Amy is a member of the National Association of Fire Investigators, the Society of Fire Protection Engineers, the National Fire Protection Association and the American Institute of Chemical Engineers.