CHECK OUT THAT RACK! – The Importance of Inspecting Storage Racks for Proper Installation

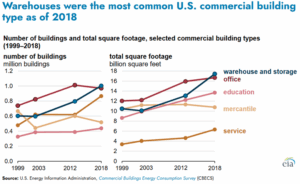

People have too much “stuff”. Manufacturers, retailers, wholesalers, and commercial enterprises all carry inventory of “stuff”, too. According to the Energy Information Administration’s (EIA’s) own statistics, in 2018, the US had over 17.4 billion ft2 of warehouse and storage. Growing from just 13 billion ft2 in 2012, warehouse and storage space is the fastest growing and now the largest use of commercial space in the US, overtaking office space for the first time in modern history.

Almost every one of those buildings contains storage racks. And this doesn’t include the mercantile spaces. You can go to a big box retailer and buy cereal from a lower shelf while pallets of grain or packaged drinks sit 20-30 feet above, waiting to be introduced to the customer.

There is no specific OSHA regulation for anchoring storage racks – which are available in myriad variations. Improper (or missing!) anchorage of even single-level storage racks represents a huge problem for property damage or injury. Side loads from passersby, loaders or material removal can tip over racks. Steel beams falling even a few feet can do enough damage to crush inventory, break bones, or even kill.

A standard pallet storage rack column. Notice the unused anchor hole on the bottom plate. Oftentimes only one anchor hole must be bolted down. Left completely unattached to the floor, however, storage racks are not installed according to ANSI MH16.1. They can lift, slip or tip over, creating possible damage to inventory or harm to bystanders.

This is why ANSI MH16.1 section 1.4.7 prescribes minimum anchorage at every column. For example, the 2012 version states:

The bottom of all columns shall be furnished with column base plates, as specified in section 7.1. All rack columns shall be anchored to the floor with anchor bolts, which shall be designed in accordance with Section 7.3, to resist all applicable forces as described in section 2.1 or Section 2.2.

Each column in a storage rack must be anchored to the ground according to the ANSI standard. But many installations do not use anchors, and the IBC does not explicitly require anchors on every storage rack (the IBC focuses on seismic loading).

Local building codes vary as to rack installation inspections. In South Carolina, for example, any rack over 6 ft. tall requires permitting in many jurisdictions. Once the racks have been installed, they are part of the structure. Fire codes also govern the materials stored on racks.

Center of Gravity

Sometimes, there is a need to determine how eccentric a storage rack’s weight has become. I’ve seen cantilevered storage of steel beams where the main column failed by bending due to eccentric loading (I.E., once cantilevered side had too much weight, causing the main support beam to bend). The center of gravity for stored material can be tedious to calculate by hand, but its concept is relatively simple. The one-dimensional center of gravity formula is as follows:

CG=Σ(ℎ×)/Σℎ

Engineers and CAD professionals can easily calculate weight based on worst case scenarios for any given storage rack and set of conditions. Doing so can help the user decide how to label their racks for maximum capacity (which is also recommended in ANSI MH16.1).

Among the safety features suggested for high-traffic areas, high-visibility base protection shields can prevent accidental damage to columns and offer barriers that can be repaired without calling in storage rack professionals. Image courtesy of Pixabay.

Whose Responsibility is Safe Installation?

Leased buildings sometimes come with racks installed by the building owner. Other times, the manufacturer may intend to load light materials onto racks, or inspections get missed during a rearrangement of a warehouse space in a manufacturing facility. But at the end of the day, the business loading the racks must understand the racks’ limitations.

Storage racks are static, easily ignored parts of our manufacturing environment. When properly installed and maintained, they perform their duty across every industry. Falls, damaged inventory, and lost work all present hazards if left unchecked. Skilled forensic engineers with analytical experience and knowledge of ANSI MH16.1 are ideally suited for identifying whether storage rack failures originated with the manufacturer, installer or somewhere else. Give us a call at The Warren Group if you would like to discuss storage rack-related issues.

Brian Tenace is a Licensed Professional Engineer and holds a FenestrationMaster® Professional Certification. He has over 15 years of manufacturing and machine design experience in production and quality-driven environments. Brian earned a Master of Science in Mechanical Engineering from the University of Florida. Over his engineering career, Brian worked in fenestration design in addition to designing hardware, above/below ground spill containment vessels, extrusions, dies and molds. He conducted root cause analyses for fatigue, weld, and corrosion failures in steel, springs, pressure vents and sheet metals. He developed tests according to standards and custom specifications as needed, along with modifying manufacturing processes. His failure analysis experience includes impact testing, design for ballistic protection, water infiltration resistance and corrosion. Brian has an in-depth knowledge of many standards with emphasis on fenestration standards and impact standards. Brian regularly investigates property damage claims involving machinery and equipment in a variety of environments, as well as personal injury, wrongful death, and product liability claims for both insurance adjusters and attorneys.