There are few things as comforting to me during the winter months as a warm fire burning in the fireplace. And in this case, I am talking the real deal, the kind that warms you multiple times; from cutting, splitting and stacking the firewood until finally lighting a fire in the fireplace. However, just like your parents taught you, fire can be dangerous. And having an actual fire in your home fireplace comes with some required maintenance to ensure you can safely control the fire and keep it where it belongs.

According to the United States Consumer Products Safety Commission, there were an average of 22,300 fires per year caused by a fireplace, chimney or chimney connector for the years 2012-2014. As a volunteer firefighter in my community, I have responded to a number of these types of fires.

Chimney fires can go undetected at times, but they often alert the residents with the characteristic roaring or rushing of wind sound. Some people have described it to me as sounding like a train. Regardless, it is a situation that needs to be promptly addressed. It is usually not difficult to respond to the location of a chimney fire because the chimney will often resemble a roman candle. Embers will often be forcefully propelled out of the top of the chimney and can set the roof on fire rather easily.

The International Building Code and the International Residential Code both cover construction aspects for fireplace, chimney, and hearth construction. The National Fire Protection Association publishes NFPA 211, Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances. These codes, as well as this standard, provide information not only for the construction of chimneys and fireplaces, but also for maintaining your chimney. Key to the maintenance of your chimney is an inspection and the associated cleaning. It is recommended that the inspection and cleaning be performed by a qualified person. The Chimney Safety Institute of America comes to mind and provides certification through an exam for chimney sweeps.

So why is it necessary to clean your chimney? The chimney serves several purposes, one is to remove the products of combustion from the fireplace and keep them out of your home. Most people think of just “smoke” when they think of a fire, but that is only part of the equation. The components of smoke include, but are not limited to, carbon dioxide, water vapor, particulate matter, hydrocarbons and other organic chemicals. These carbon-containing chemicals condense on the cool (relatively speaking) walls of the chimney liner and form creosote. Creosote has an auto ignition temperature of 451 degrees F per NFPA research. When creosote burns, it makes a roaring hot fire that can damage the chimney and chimney liner as well as lead to a fire in the residence. An annual inspection and cleaning are recommended for the safe operation of a wood burning fireplace.

One of the more interesting fires I responded to during my 20-plus years in the volunteer fire service involved a fire that started because of poor construction techniques in a chimney. The home was constructed in the early 1960’s. The call came in in the early hours of the morning and the first on scene fire crew reported fire extending through the roof of the residence. The fire was extinguished with no injuries or loss of life. With the fire under control, investigation for the origin and cause commenced. The walls of the home were in relatively good shape from approximately eye level down, but it was lacking a large portion of the roof on half of the structure. So, observation could tell you that the fire had to originate in the attic area above the occupants and not from below.

This led to an examination of the chimney of the residence. A picture of the chimney is shown below. One can observe that the brickwork above the roofline is something most homeowners would be satisfied with. The work that was hidden behind the walls was another story altogether. The use of broken and “cull” brick can easily be seen. Mortar can degrade over time, especially when exposed to repeated heating and cooling cycles. Mortar was indeed missing in between the joints of the brick and some bricks are even turned sideways with the holes facing in towards the chimney flue and out towards the wooden structure of the home. Close inspection revealed that the chimney was constructed without a liner. You could shine a flashlight through the cracks created by the missing mortar and see the inside of the unlined chimney flue! The owner had indeed had a fire in the fireplace that night before going to bed and conditions were right for embers or perhaps even burning creosote to escape the flue and set a fire in the attic.

The fire started in the attic over the heads of the sleeping occupants, cut off from the smoke detectors by the ceiling. Fortunately for the family, the doorbell wiring began to fail due to fire attack and the sound of the ringing doorbell woke the occupants before the fire was able to burn down through the ceiling or worse, the burning ceiling and attic collapsed on them! The entire family escaped unharmed.

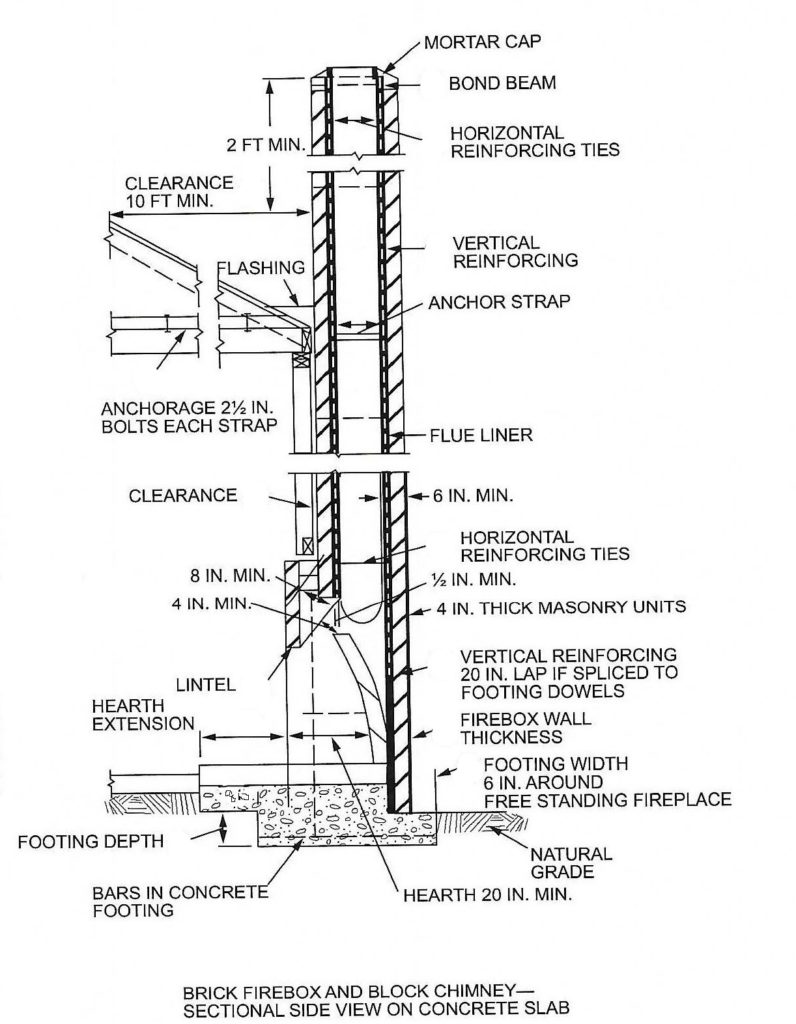

A schematic of the basics of a proper masonry chimney as illustrated in the International Residential Code is shown below. Note the use of a liner would aid in preventing just this type of fire as discussed above. A properly lined, inspected, and maintained chimney would have gone a long way toward preventing a fire of this nature.

So, the next time you settle in for the evening to enjoy a warm fire, please be sure you didn’t skip the inspection and maintenance of your chimney and fireplace. The consequences of neglecting your chimney should not be underestimated.

Chad Jones, PE, CFEI, CMSE has a Bachelor of Science in Mechanical Engineering from Clemson University. Chad has over 20 years of engineering experience including mechanical, process, and manufacturing engineering. This work has included equipment design, machine safeguarding, cost estimating and safety compliance. Chad also has over 10 years of commercial, industrial, and residential HVAC and plumbing design experience. Chad is a Certified Fire and Explosion Investigator and IFSAC certified Firefighter II in Greenwood County, South Carolina.