Previously, Warren posted the first installment of a series on losses associated with heating systems. The first article looked at central forced air furnaces. This new article will look at a common form of supplemental or secondary heat, oil filled electric radiant heaters. These heaters are commonly used to provide extra heating in areas that are lacking in central heating capacity. Another rationale for their use arises from manufacturer’s claims that the portable heating units can lower your power bill. This is based on the idea that local spot heating from the unit allows you to lower your central heating thermostat setting and save energy overall.

Figure 1: A view of a typical oil filled electric space heater. This photo shows an exterior view with the operators’ controls.

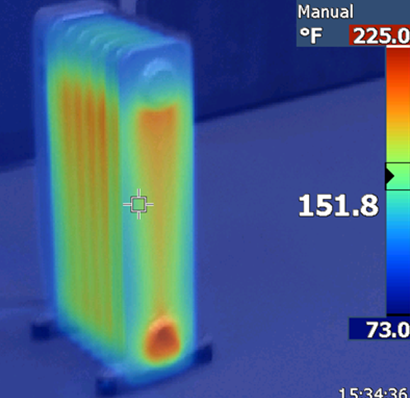

Figure 2: This photo is a thermal IR image with the thermostat set at a medium setting. The hottest location at the bottom corresponds to the heating element location.

A typical oil filled radiant heater is shown in Figures 1 and 2. The figures show both the normal exterior of the product and an infrared image showing the unit’s temperature after a few hours of operation.

Several codes and standards address oil filled radiant heaters (and other electric space heaters). These include UL 1278, Movable and Wall-or Ceiling-Hung Electric Room Heaters. Codes such as the International Fire Code (IFC) require portable electrical space heaters be used in certain safe ways. The 2018 IFC edition allows use of portable electric spaces heaters, but requires that heaters be listed and labeled, plugged directly into receptacles (no extension cord) and be kept at least 3 feet from combustible materials. The National Electric Code (NFPA 70) has some provisions that impact the application and design of portable space heaters. Portable spaces heaters in the United States are generally designed for use with 15 and 20 amp 120 volt standard convenience receptacles. Article 210.23 (1) of the NEC limits the rating of a single cord and plug connected device to 80% of the branch circuit rating. This has the practical effect of limiting the heating capacity of electric space heaters to around 1500 Watts for a 15 amp circuit.

Oil filled radiant heaters usually operate without incident, but occasionally they can be involved in losses, even causing fires. Types of losses fall into several categories many of which relate to improper usage or poor maintenance, although defects in the design or construction of equipment do occur.

Any object placed near and around people and their children and pets is bound to get tipped over; Mr. Murphy being ever-present in the universe. Interestingly, oil filled radiant heaters are not required to have a ‘tip-over’ switch per se. Instead they must pass a tip-over test to be UL listed to the aforementioned standard. That could mean they employ a high temperature cut off switch or other control mechanism. This control device deenergizes the heating element before fire can occur.

Warren has investigated cases where these heaters have continued to operate after tipping over. The figure below shows an element which was operating only partly submerged.

Figure 3: A heating element from an oil filled heater accused of failing and causing a burn injury by discharging its hot oil. One side of the element is distorted and covered with burned oil residue. This is an indication that the unit had been operating while laying on its side.

However, just because a heater is found on its side doesn’t mean that was its orientation when it was involved in a fire. Fire-fighting efforts could topple a previously upright oil-filled heater. Studies on these heaters with different pre-fire orientations have shown that the differences in how the metal deforms can indicate whether the heater was upright or on its side when burned. This is dictated by the difference in behavior of the wetted and unwetted metal of the oil-filled heater.

To remove the tip-over risk, it’s always advisable to turn off and unplug any oil filled radiant heater when it will be in a room unattended.

As President of The Warren Group, Jennifer Morningstar, B.S.Ch.E, P.E., CFEI, has over 20 years of engineering experience. A licensed professional engineer in several states and a NAFI Certified Fire and Explosion Investigator, she holds a Bachelor of Science Degree in Chemical Engineering from Virginia Polytechnic Institute and State University, as well as a Master of Business Administration from the University of South Carolina. Over her 20-year engineering career, Jennifer has conducted forensic investigations involving chemical release/exposure, OSHA process safety management, industrial accident investigation, equipment failures, fires & explosions, and scope of damage/cost to repair. Jennifer is a member of the National Association of Fire Investigators (NAFI), the South Carolina chapter of the International Association of Arson Investigators (SCIAAI), and the American Institute of Chemical Engineers (AIChE).