In my previous blog , I discussed the most basic and most common fire system type: wet sprinkler systems. The possible failure areas discussed with wet systems will also apply to dry sprinkler systems (control valves closed, obstructions, issues in the system, installation, or deficiencies with inspection, testing, and maintenance). Dry systems are even more prone to obstructions than wet systems, so close attention should be paid to that possibility.

In this edition, the focus is on dry systems, and issues specific to them.

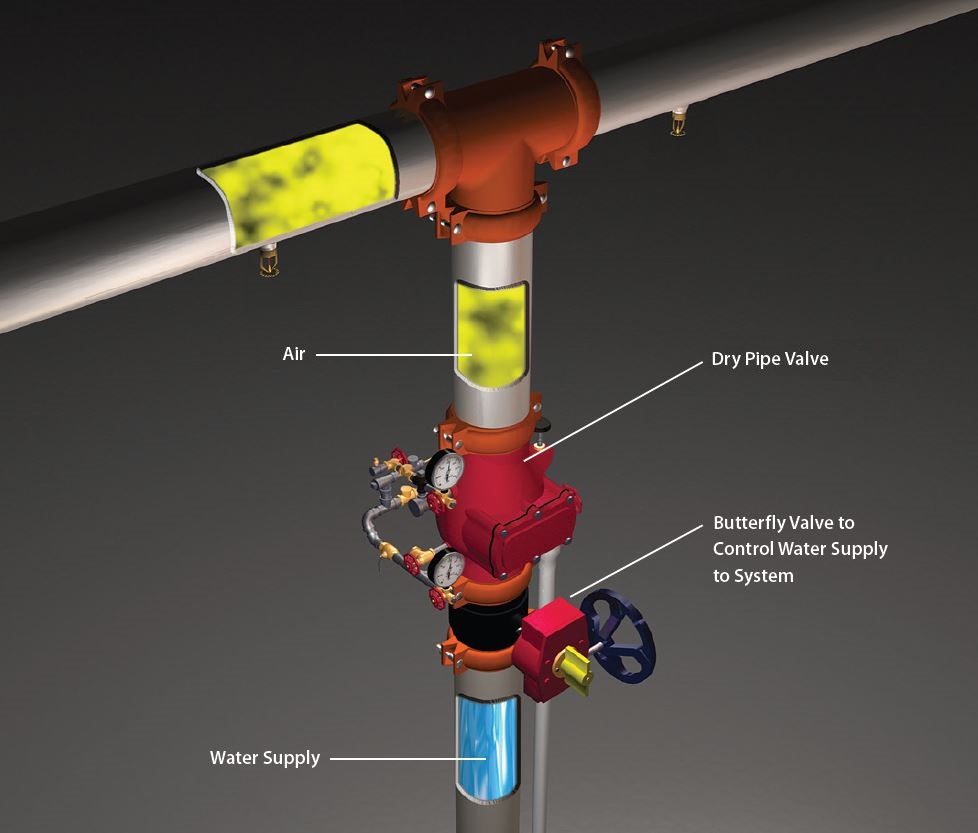

Dry sprinkler systems are used to protect areas subject to freezing temperatures, such as loading docks, attics, or unheated warehouses. The sprinkler piping in an unheated area has pressurized air in it instead of water. Water is held back by the air pressure at the dry valve, which would be located in a heated area.

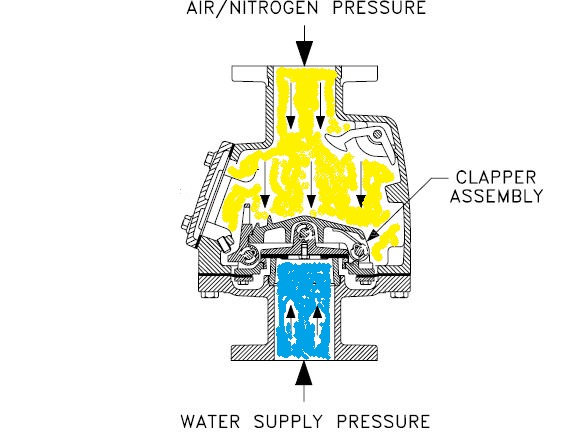

There are two kinds of dry valves: differential and pilot-operated, with the differential type being much more common. “Differential” refers to a difference in water and air pressure. In dry valves, a relatively small pressure

of air holds back a much greater (possibly 4 – 6 times greater) pressure of water to hold the valve in the set position. This is possible because the surface area of the clapper that the air acts on is much larger than the surface area of the clapper that the water acts on.

Possible Issues

The root causes of potential issues with dry systems are many, but for purposes of this article I’ll boil them down to three categories:

Inadequate performance during a fire. In addition to shared issues with wet systems, it is possible that the valve failed to trip or the valve trip was delayed. Ask me about: water columning, drainback, gridded systems, or accelerators (not the automobile kind!).

Holey dry piping leads to unexpected indoor shower. Pinhole leaks are likely to eventually develop over time in dry system piping. Pinhole leaks can be caught early using an air leak test which should be performed every 3 years. If pinhole leaks are not discovered and corrected, eventually the dry valve will trip once air compressor or air maintenance device can’t keep up with the leakage rate of air. And then, water will be exiting any and all pinholes in the piping (picture a garden hose with holes, but worse!). Murphy’s Law ensures water will make it into the worst-possible places: the CEO’s office, the server room, critical files storage, electrical cabinets, you know the drill. Ask me about: contributing factors for pinhole leak development.

Piping freeze damage leads to water damage in the building. This happens when water gets into, or was already sitting where it shouldn’t have been, then froze. The ice broke some piping, which then leaked once the ice thawed (see the case study that follows). Ask me about: pitch, low-point drains, water columning, or adequate heat in riser rooms.

Case Study: Pitch -Not- Perfect

A wood-framed office building had an attic space protected by a dry sprinkler system. During a spell of unusually bitter-cold weather, the dry valve tripped, then water began flowing from a broken spot in the piping. The water flowed into the floor below, causing damage to equipment, ceiling, wallboards, and flooring. Warren’s investigation found a section of inadequately pitched piping with a low spot, likely present from installation. Water could not properly drain from this low spot. The water trapped in the low spot froze and caused the break. As the temperature warmed and the ice melted, air began to leak from the system until the compressor could no longer keep up, then the dry valve tripped.

If you need an investigation of a fire involving a possible dry sprinkler failure, please call our experienced fire protection experts at Warren.

Amy Anderson, PE has a Bachelor of Science in Chemical Engineering from Clemson University. Amy has over 20 years of engineering experience including property loss prevention engineering specializing in fire protection, chemical and pharmaceutical facilities. She has partnered with clients to identify, assess, avoid, and reduce risk at their commercial and industrial properties. Additionally, she has assisted with the development of building and fire protection specifications, reviewed plans and performed site visits. She has reviewed project documents for compliance with applicable standards – construction, fire protection, process, and combustible dust hazards. Amy is a member of the National Association of Fire Investigators, the Society of Fire Protection Engineers, the National Fire Protection Association and the American Institute of Chemical Engineers.