Statistics predict that about half grill owners will be firing them up this upcoming Memorial Day weekend [i]. Let’s look over a propane grill, as if we had just pulled it out for the grilling season, for some tips and red flags. Not beef tips or how to get the perfect sear on your steak – safety tips! Besides hot surfaces, a gas grill serves up hazards related to flammable gases: fires, explosions, and flash fires.

First, get your grill’s manual, READ IT and FOLLOW IT. And, hey, it may give you a handy reference for replacement part numbers.

Let’s say our hypothetical gas grill has a typical and common 20 lb propane cylinder. Look it over. It should be in good condition, with no dents, no bulges, no corrosion, no deep rust, no evidence of heat or fire exposure.

From the time of manufacture, these cylinders are good for 12 years, and then they require requalification. Requalification can be done by one of three ways:

- Visual inspection

- Proof pressure method

- Volumetric expansion method test.

This cylinder was manufactured in April of 2017 (green ovals). It was requalified by a visual inspection (designated with letter E following the 18) in January of 2018 (blue ovals), with the inspector’s designation in the numbers below the date. The visual inspection is good for 5 years. Since January 2018 is over 5 years ago, the cylinder is out of qualification.

Let’s check the cylinder valve’s seal next.

Hang on, we can’t see the seal very well for that mud dauber’s nest! Hmm, must not have put the valve cover on in the fall. Let’s clean him out so we can get a better look at that seal – kidding!

Good thing I had a spare cylinder. Oh no, the valve seal doesn’t look very good on this one. This cylinder needs to be replaced, and I may need to make different plans for dinner tonight.

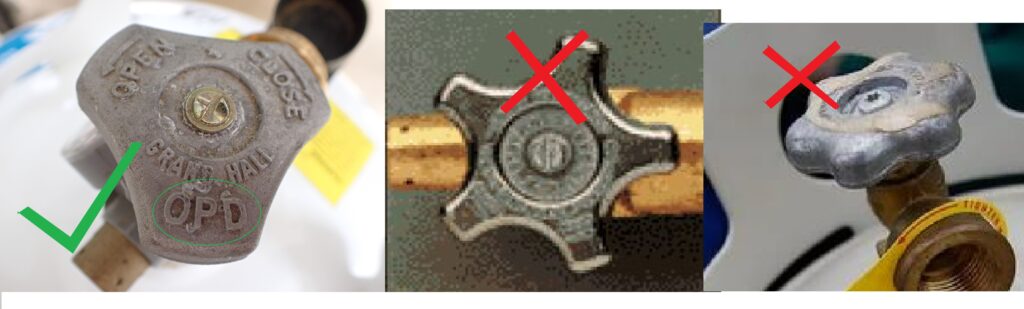

Next, look at the propane cylinder’s handwheel: it should be triangular and not a star or rounded star. (This is for the size and type of portable cylinder that would be used with grills, turkey fryers, outdoor griddles, the like.)

Why is the shape of the handwheel important? The shape of the handwheel indicates the presence or lack of an OPD (overfill protection device). The triangular handwheel will have “OPD” on it, and the body of the valve below will have “OPD” in the casting. You may also see a sticker indicating the presence of an OPD. If the cylinder has a star-shaped handle, that speaks to its age because that standard was changed in 1998. Overfilling a cylinder creates a fire and explosion hazard because, in an overfilled cylinder, there’s not enough head space for expansion as the temperature rises, which means the pressure inside the cylinder goes up. The pressure can increase and activate the pressure relief valve located on the main valve. While the pressure relief valve opening protects the cylinder from failing catastrophically, there is flammable gas being released from the cylinder.

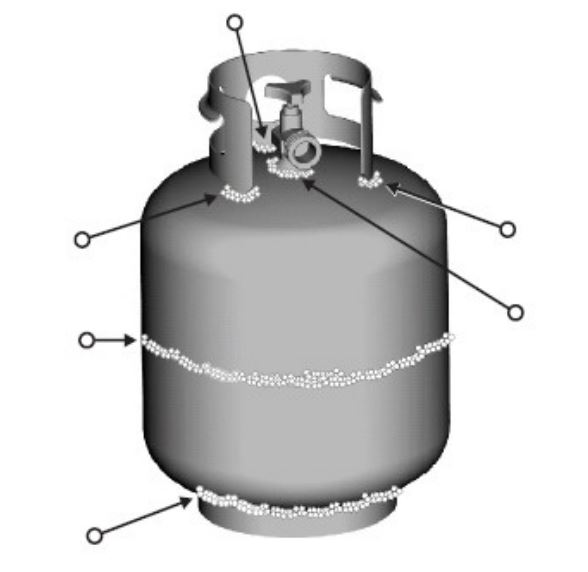

What’s left to do with the cylinder is to check it for leaks around the welds using soapy water solution, which is simply a mixture of 1 part water and 1 part dishwashing liquid.

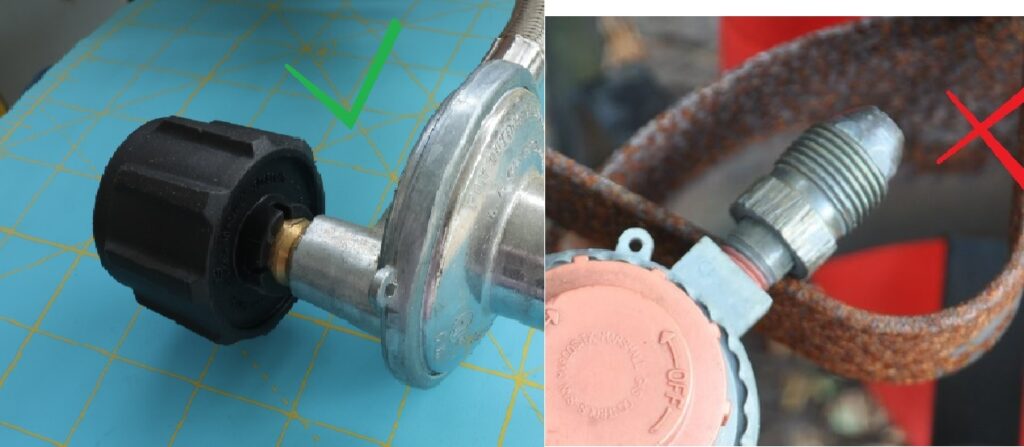

On to the connector and hose. The approved type of connection, a Type 1 (DOT), is designed not to allow the flow of gas until a positive gas seal has been achieved. The POL (CGA 510) type connection is no longer allowed for connection to propane cylinders used on grills. Check the end of the connection, too, because mud daubers do love holes!

Inspect the hose for signs of abrasion, wear, or cuts. Inspect the regulator.

Check the hose-to-cylinder connection and other joints for leaks using soapy water solution.

Moving on to the grill itself!

How do the burners look? (Take heart! The ANSI standard requires that burners must be easily removable and no special tools should be required). Burner ports (the small holes down the top or sides) should be clear.

The burner tube and venturi should be cleared of insects and insect nests. Clogging or obstructions inside the burner can result in flash-back or fire under the grill.

Burners come in different configurations and are made of different materials; check the owner’s manual for specific instructions on correct cleaning methods. It’s unlikely that one can see down the length of the burner to inspect for obstructions, so ensuring the burners are clear may involve a burner brush, bottle brush, or wire.

Burners come in different configurations and are made of different materials; check the owner’s manual for specific instructions on correct cleaning methods. It’s unlikely that one can see down the length of the burner to inspect for obstructions, so ensuring the burners are clear may involve a burner brush, bottle brush, or wire.

Check the functioning of ignitors and electrodes. Careful attention to correctly lighting a grill or attempting re-lighting following flame-out is of utmost importance. Applying an ignition source to an accumulation of flammable gas can result in an explosion or flash fire.

Clean the interior of the grill, grease pan and grease cup per your owner’s manual. Failure to clean a grill is a leading contributing factor of grill firesi.

If this has whetted your appetite, check out Warren’s September 2020 blog, Don’t Get Burned With Your Gas Grill! For a host of grilling safety tips and videos, see NFPA’s page on Grilling: https://www.nfpa.org/Public-Education/Fire-causes-and-risks/Seasonal-fire-causes/Grilling

Amy Anderson, PE, CFEI, has a Bachelor of Science in Chemical Engineering from Clemson University and is a licensed Professional Engineer in Fire Protection, as well as a Certified Fire and Explosion Investigator. Amy has over 20 years of engineering experience including property loss prevention engineering specializing in fire protection, chemical and pharmaceutical facilities. She has partnered with clients to identify, assess, avoid, and reduce risk at their commercial and industrial properties. Additionally, she has assisted with the development of building and fire protection specifications, reviewed plans and performed site visits. She has reviewed project documents for compliance with applicable standards – construction, fire protection, process, and combustible dust hazards. Amy is a member of the National Association of Fire Investigators, the Society of Fire Protection Engineers, the National Fire Protection Association and the American Institute of Chemical Engineers.

[i] https://www.nfpa.org//-/media/Files/News-and-Research/Fire-statistics-and-reports/US-Fire-Problem/Fire-causes/osGrills.pdf