CHECK OUT THAT RACK! – The Importance of Inspecting Storage Racks for Proper Installation

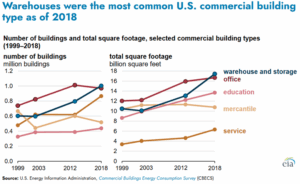

People have too much “stuff”. Manufacturers, retailers, wholesalers, and commercial enterprises all carry inventory of “stuff”, too. According to the Energy Information Administration’s (EIA’s) own statistics, in 2018, the US had over 17.4 billion ft2 of warehouse and storage. Growing from just 13 billion ft2 in 2012, warehouse and storage space is the fastest growing and now the largest use of commercial space in the US, overtaking office space for the first time in modern history.

Almost every one of those buildings contains storage racks. And this doesn’t include the mercantile spaces. You can go to a big box retailer and buy cereal from a lower shelf while pallets of grain or packaged drinks sit 20-30 feet above, waiting to be introduced to the customer.

There is no specific OSHA regulation for anchoring storage racks – Read More