Windows, and their interface with the exterior walls, are an important part of a building’s envelope that resists the intrusion of water. Most builders take many precautions to protect a house from water damage. One of the most important factors in keeping the water out is the installation of window flashing, a thin material that prevents water from seeping in around a window. Over time, even a tiny gap around a window that allows water to enter can result in fungal growth, wood decay, and structural damage that can end up requiring costly repairs.

Expensive water leaks correlated with windows can often occur between the window units and their frames, but the most predominant leakage paths appear to be based on poor construction and installation techniques of the window and wall interfaces. Water infiltrating through these paths can cause considerable amounts of damage to the wooden framing which often is concealed until the water damage has become widespread. The water management components for windows include the following:

- Sills and thresholds

- Water-resistive barriers

- Flashings

- Caulking

- Proper integration with the wall’s water-resistive system

- Continuous drainage paths

The American Society for Testing and Materials (ASTM) Standard E2112, “Standard Practice for Installation of Exterior Windows, Doors & Skylights”, as well as the International Residential Code (IRC), provide guidance for the performance and construction requirements for exterior windows. The International Code Council (ICC) provides direction.

“There are two key principles for effective flashing at windows and doors to allow water to drain down the face of the wall and away from the building:

- Integrate flashing with the water-resistive barrier (WRB), e.g., house wrap.

- Install membranes shingle-fashion where the top layer of the WRB or flashing laps over the bottom layer to prevent water draining behind the bottom layer”.

One often overlooked component of window installation is the slope of the windowsill. Windowsills that lack a positive slope away are common in the field and contribute greatly to potential water intrusion, particularly when sill pan flashing is omitted in the sub-sill portion of the wall below the window units. Windowsills that are nearly horizontal or, worse yet, slope back toward the interior of the building, create relatively large edges that can collect water and can expedite deterioration of sealants and lead to water intrusion.

A good construction practice is to have a pronounced slope that aids in prompt drainage of water, thus deflecting it away from susceptible sill interfaces. The Brick Industry Association recommends a slope of 15 degrees away from exterior windows for brick veneer applications. This can be achieved by proper planning with the brick mason and determining the height to the window opening.

Another important tool to prevent water intrusion is the use of a water-resistive barrier (WRB). This is critical in the areas around the window opening, which creates interruptions in the drainage plane. Careful attention should be paid to the details for window openings during the design and installation of the water resistive elements around them to ensure proper water management in these areas. Vital points to remember for the installation of WRB is the preparation of the opening with house wrap, felt, or building paper, and the integration with the sill, jamb, and head flashings in order to maintain a continuous drainage plane. As such, there is prescriptive information in the ASTM E2112 document.

Image Credit: Brick Industry Association, Water Penetration Resistance-Design https://www.gobrick.com

The sub-sill framing below the window opening is another area that is susceptible to water leaks. This typically occurs at the lower corners of the rough opening in the wall, usually where the coverage of the water resistive barrier is minimal. As such, the pan or sill flashing serves to protect the sub-sill framing of the wall and interior portions of a residence beneath the window openings that are susceptible to leakage. Consequently, the sub-sill drainage provided by pan or sill flashing is crucial in achieving the performance and longevity of installed windows. Lastly, the jamb and head flashings will provide reinforcement to prevent water intrusion.

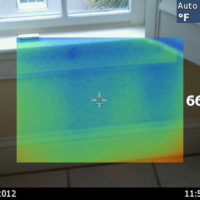

So, you may ask, “How can we find water leaks in our residence without an invasive approach?” A non-destructive method to identify water leaks in windows is by thermal imaging. Thermal imaging is an essential tool for detecting moisture intrusion. During an investigation, the infrared technology can quickly and non-invasively zero in on the area of concern to find anomalies that may be created by moisture cooling. Monitoring the weather is crucial for successful results. Consequently, it is imperative to choose the optimum time to test and maintain a proper temperature control. For example, the greater the span in temperature from the outside to the inside of the residence, the better the thermal results. As such, a warm or hot climate is excellent for thermal inspections since air conditioning is cooling the interior of a residence. The following image depicts an example of this technique.

As can be seen in the above image, the blue areas below the windowsill illustrate an example of a concealed water leak behind the gypsum wall board. It should be noted that the thermal images can reveal a growing problem that can lead to more extensive water damage to a residence.

This residence had substantial water leaks coming through the windows, consequently developing extensive wood decay around the perimeter of the window frame. Due to the ability to remain undetected, hidden water leaks can grow to become large losses. Using non-destructive tools, such as the Fluke thermal imaging camera, the source of the leak can be identified without unnecessary destruction of property. Getting to the source of the problem as soon as possible is key to avoiding potentially extensive repair work.

Founded in 1997, The Warren Group, forensic engineers and consultants provides technical investigations and analysis of personal injury and property claims as well as expert testimony for insurance adjusters and attorneys. Extremely well versed in the disciplines of mechanical, electrical, chemical, structural, accident reconstruction and fire and explosion investigation, our engineers and consultants are known for delivering the truth — origin, cause, responsibility and cost of an event or claim — with unmistakable clarity.