Heavy machinery fires are often caused by hydraulic hose failures. Pressurized hydraulic fluid escaping from a failed hose assembly can be atomized into a fine spray that can be ignited by heated engine surfaces such as the engine exhaust or turbocharger.

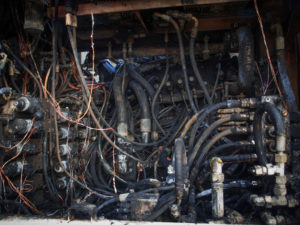

Hydraulic hoses often fail due to age and wear, requiring regular inspection and replacement of hydraulic hoses to prevent failures. Hoses may also fail if they are misrouted. Misrouting can lead to the hose being pinched or causing it to chafe against a sharp metal surface.

Hydraulic hoses can also fail due to improper assembly. Hydraulic hose assemblies are made by cutting a section of hose to length and then crimping metal fittings on each end. Hydraulic hoses differ in material and construction by manufacturer but generally have three layers; an inner leakproof layer that conveys the hydraulic fluid, a reinforcing layer of metal braid, and an elastomeric outer layer that protects the inner layers from wear and environmental exposure.

Hydraulic hoses must be assembled with compatible fittings and strict adherence to the manufacturer’s directions. The ends of some hydraulic hoses must have the outer layer removed before the fitting is installed, a process called skiving, though not all hoses require skiving. The fittings must be fully installed on a squarely cut hose prior to crimping them in place. The correct die and crimping machine specified by the hose manufacturer must be used. The fittings must be measured after crimping to ensure that they were crimped to the manufacturer’s specifications.

Fittings can separate from the hose ends under pressure if they are under or over-crimped, the hose is not fully inserted into the fitting before crimping, an incompatible fitting is used, or the hose is not prepared in accordance with the manufacturer’s directions. Over-crimping also can provide a leak path within the fitting that allows the hydraulic fluid to migrate between the outer and reinforcing layers, leading to bubbles in the hose near the fitting and eventually rupturing the outer layer, exposing the hydraulic fluid to possible ignition sources. Hoses with visible bubbles should be replaced immediately.

When a fire occurs, hydraulic hoses are often consumed, complicating the evaluation of whether a hose failure led to the fire. Visual inspection and micrometer measurements can determine whether a suspect hose fitting was properly crimped to the correct diameter. If a hose is partially consumed, the fitting on the undamaged portion of the hose can be sectioned and examined for proper assembly.

Please do not hesitate to contact Warren should you have a heavy equipment fire that may have been caused by a hydraulic hose failure.

John Phillips, senior consulting engineer at Warren, has more than 35 years of crane and heavy equipment experience and more than 25 years of experience in forensic engineering. A licensed professional engineer in South Carolina, North Carolina, Georgia, Louisiana and Ohio, he’s NCEES registered both as a model engineer and with The United States Council for International Engineering Practice, USCIEP. John has designed crane systems, supervised installation, tested and certified lifting equipment even serving as a project engineer for maintenance and certification of nuclear weapon lifting and handling systems. His extensive experience helps him determine the cause and scope of damage for crane, hoist and other lift equipment incidents.