Firefighter Burned Due to Improper Industrial Oven Design and Operation

Industrial ovens and furnaces are used in many manufacturing processes. One use of industrial ovens is for drying and curing coatings on fabrics.

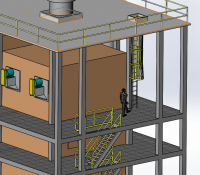

We investigated a fire loss involving a very large oven, 10 stories high, used for curing coatings on an industrial fabric. A young firefighter was burned in response to this fire, one of a string of many fires that had occurred involving the oven.