Heat Exchanger Failures Will Shut Your Process Down

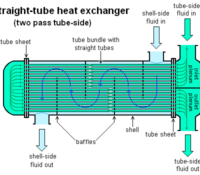

Heat exchangers, as the name implies, are used to bring a process stream to a desired temperature. They can heat or cool either gases or liquids. They are fairly intricate in their construction, therefore not the cheapest piece of equipment to purchase. For that reason, facilities don’t keep “spare” exchangers lying around, so when they fail catastrophically, the entire manufacturing process goes down with them… and stays down until they are fixed or replaced. Ow!